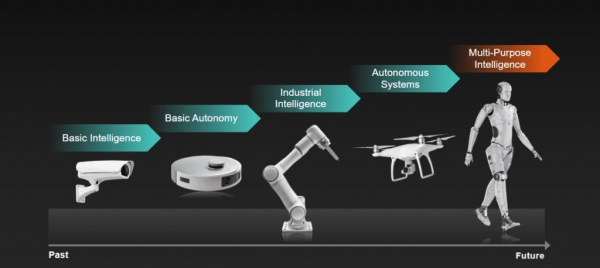

Today, Physical AI is already taking shape in the real world—appearing in everything from self‑driving vehicles navigating cities from San Francisco to Shenzhen, to autonomous robots operating in industrial warehouses and drones delivering packages. But the future of Physical AI will extend even further, spanning everything from humanoid robots to autonomous imaging systems in healthcare and a wide range of other real‑world applications. This next phase of AI is bringing AI beyond data centers and directly into the physical world in the form of machines that interact with their environments in real time.

However, delivering these capabilities at scale introduces a new set of constraints and opportunities for semiconductor technology. Multi-modal sensing, distributed intelligence, actuation, and power efficiency become as critical as performance itself. Purpose-built semiconductor platforms are the foundation that will enable Physical AI to move from early adoption to widespread deployment.

Purpose-built semiconductor platforms for Physical AI

Physical AI is introducing broader workloads that are reshaping the requirements for semiconductors. The requirements of Physical AI are creating a massive opportunity for GF to deliver reliable, energy-efficient, highly integrated platforms that can adapt over time.

Here’s how our platforms are enabling this next wave of Physical AI:

- GF’s industry-leading FDX platform is ideally suited for applications in Physical AI that are optimized for long battery life in small form factors, thanks to its ultra-low power and low leakage capabilities, superior RF performance, integrated power management and highly reliable operation up to 150 degrees Celsius.

- GF’s differentiated FinFET platform provides increased performance at the right power profile, fully optimized for integrated solutions, enabling efficient sensing, real-time processing, and seamless communication in real-world environments.

- Memory solutions including MRAM and RRAM offer embedded non-volatile memory options with low power consumption and the fastest access times in the market, allowing customers to build differentiated systems from scratch with pre-validated memory IP. This is critical to future-proof Physical AI designs as traditional memory scaling faces both physical and economic limits.

- Silicon photonics and RF innovation are driving high-speed connectivity by increasing speed and bandwidth of interconnects within and outside of the application, to communicate reliably across billions of devices at the lowest possible power.

- Advanced packaging and heterogeneous integration further enable Physical AI by bringing together diverse technologies—compute, memory, RF and power—into compact, efficient systems optimized for distributed deployment.

The real-time operating model behind Physical AI

As AI undergoes this fundamental shift to be present in the real world, applications in Physical AI must respond in real time to the environment around it. In our last blog, our Chief Business Officer, Mike Hogan, introduced a simple but powerful framework that defines how Physical AI functions: Sense – Think – Act – Communicate.

- Sense: Capture data from the physical environment using multimodal sensors such as audio, haptics, optical, radar, and environmental sensors.

- Think: Process and interpret that data locally to make real-time decisions, in deterministic, safe, and secure way.

- Act: Execute precise, timely actions through motors or actuators with precision feedback loops.

- Communicate: Exchange data reliably and securely across distributed systems, from edge to cloud and across devices.

However, any weakness— whether in latency, power efficiency, security or reliability—can degrade overall system performance. That’s why looking ahead, Physical AI systems will become more customized and adaptive, to optimize not just for compute but for real-world operations over long lifecycles.

Overcoming power and latency constraints of Physical AI

Power and latency are fundamental system-level constraints that shape what is possible in Physical AI. These applications operate continuously in confined thermal environments, often times without direct access to abundant energy, while simultaneously requiring real-time responsiveness. As semiconductor content increases, inefficient power consumption and excessive latency can limit performance, reduce reliability and shorten operational life.

Optimizing for power efficiency and ultra-low latency enables Physical AI systems to do more with less under power, thermal and computing constraints. This makes innovating semiconductor platforms essential to scaling Physical AI beyond pilots, and eventually into mission-critical environments.

Enabling software-defined, distributed intelligence

As Physical AI systems evolve, architectures are shifting away from centralized compute toward distributed intelligence. Rather than sending all data to the cloud or a single processor, intelligence is being placed at the interface with the real world, so that they are closer to where data is generated and actions are taken.

Software-defined architectures play a key role in this transition. By decoupling hardware from software, developers can continuously upgrade features and have the flexibility to support evolving AI models without having to redesign the actual hardware. This is especially critical in long-lived systems such as vehicles, industrial equipment and robotics platforms.

Physical AI today: Software defined vehicles

One of the most visible examples of Physical AI today is the software-defined vehicle (SDV). Today’s modern vehicles integrate hundreds of chips to support advanced driver assistance systems (ADAS), infotainment, connectivity and battery management. However, as autonomy, electrification and connectivity accelerate, semiconductor content per vehicle continues to rise. In just the last five years alone, the average semiconductor content per vehicle has risen from $700 to $1,000 and S&P Global Mobility estimates this number to continue growing to approximately $1,400 through the end of the decade.

These systems rely on high-performance sensors, real-time processing and precise actuation to improve automotive safety and user experience—all while operating under strict power and thermal constraints.

Physical AI tomorrow: Humanoid robots

The same principles extend into emerging humanoid systems, which need even higher degrees of flexibility to support evolving AI models, sensor fusion algorithms and autonomy stacks. That’s because humanoid robots require multimodal sensing to perceive their environments, distributed intelligence to process data with ultra-low latency and precise motor control to execute fluid, human-like motion in real-time with dozens of degrees of freedom.

It’s no surprise that a high-end industrial humanoid has semiconductor content that exceeds SDVs by up to four times. These growing silicon footprints make one thing clear: Scaling Physical AI will depend on platforms that can deliver real-time performance within tight power, thermal and reliability limits.

Building the foundation for the Physical AI future

As the Physical AI wave pushes intelligence from the cloud into the physical world, success is no longer defined by raw compute alone, but by the ability to deliver reliable, energy-efficient, and adaptable systems at scale. At GF, we’re continuously looking for opportunities to enhance our technology platform for this future designed for sensing, real-time decision-making, actuation and communication.

Following our recent acquisition of MIPS, we’ve layered our platforms with MIPS’ suite to better target the growing Physical AI opportunity. In the next installment of this blog, we’ll chat with MIPS CEO, Sameer Wasson, on how we’ve combined MIPS’ architecture, IP & design with GF’s optimized process technologies to advance compute workloads and deliver the deterministic real-time performance that Physical AI requires.